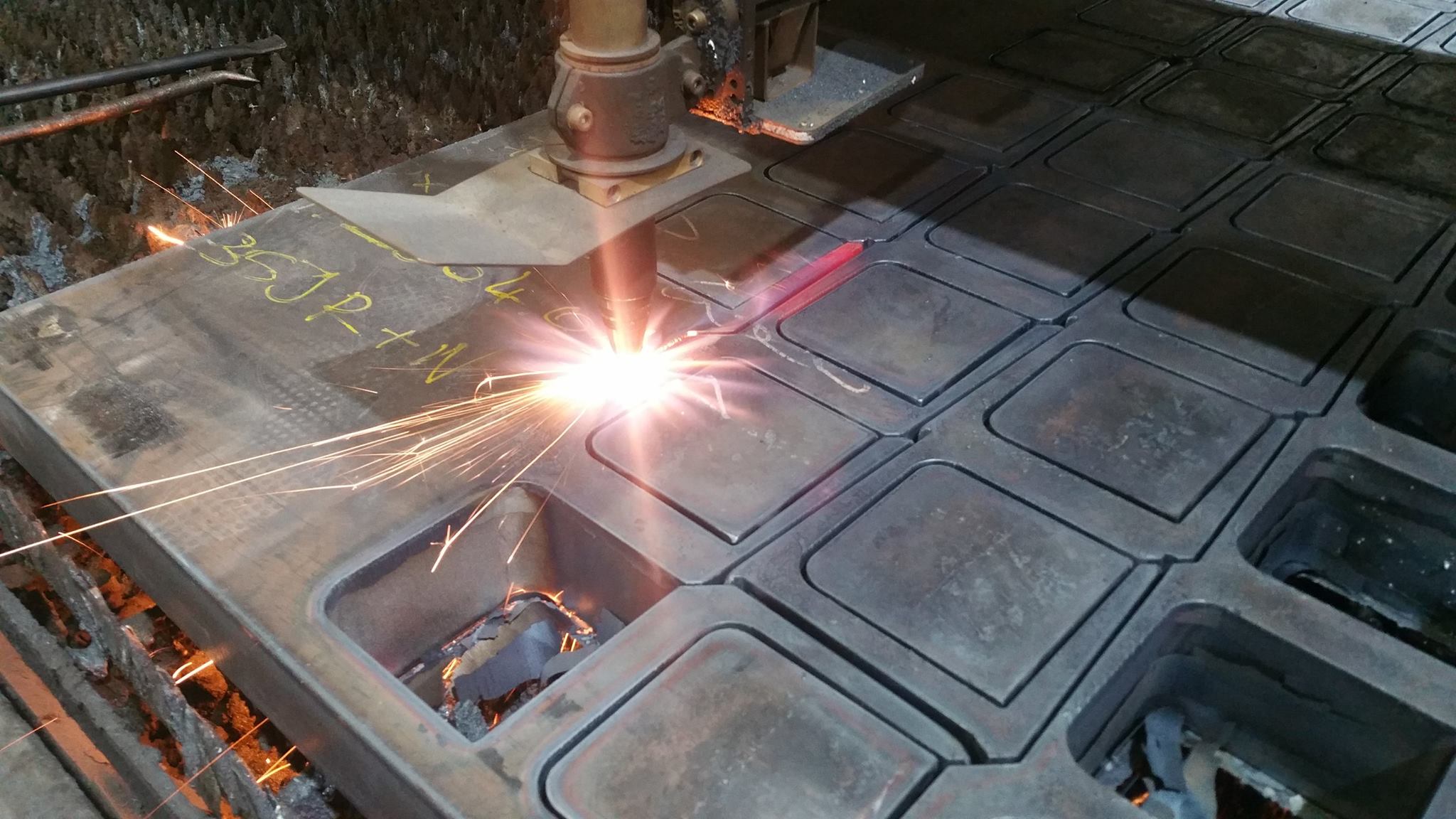

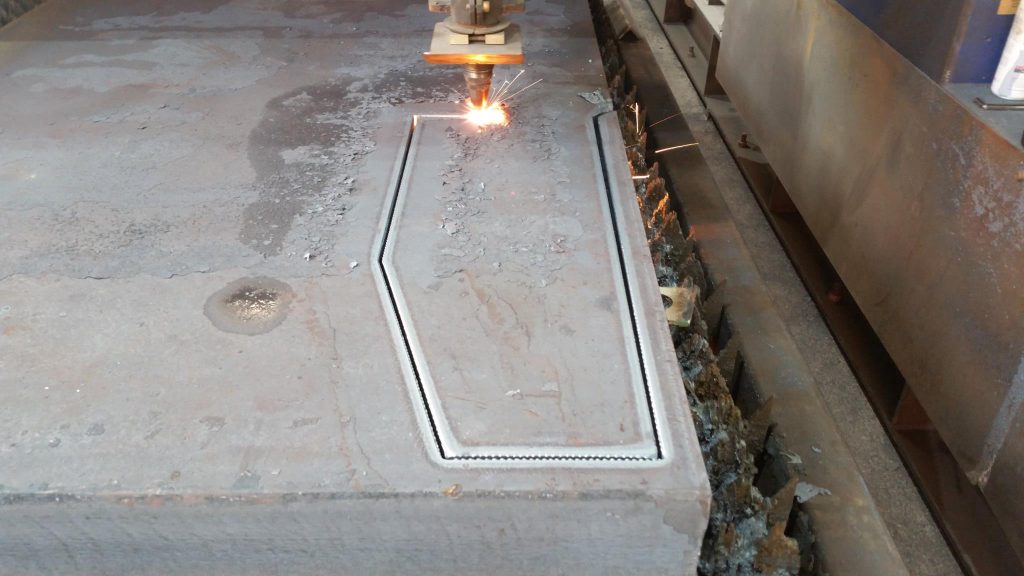

Oxy-fuel cutting is a more than 100-year-old cutting process for steel in the large material thickness range and is still one of the most important cutting process in metal processing.

Particularly in many areas of heavy industry there is no alternative to oxy-fuel cutting, as the laser or plasma beam is not suitable for material thicknesses more than 40mm for economic reasons. During the cutting process the separation point is heated to ignition temperature and than separated by a gas jet.

Steel can be cut up to 200mm thickness.

The table dimensions are 6.000x2.500mm.